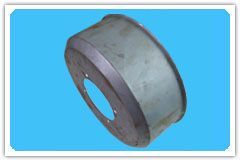

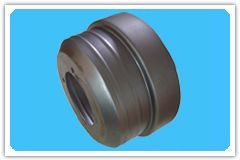

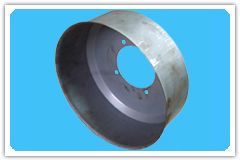

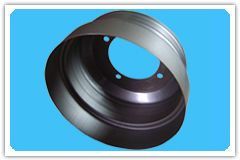

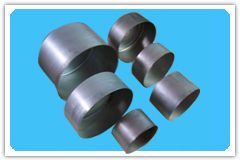

Seamless Deep Drawing

Deep drawn enclosures are commonly used as housings for electronic & mechanical components.

The kind of items produced using the deep drawing

production method range from very small eyelets to large

enclosures, the type of boxes one might find on industrial

production equipment. These enclosures are used in a variety

of applications, including relays, solenoids, RF shields and

assembly housings.

The outcome is seamless parts at an

economical price.

The Process

The deep drawing process combines many benefits of

metal spinning and stamping

with several other advantages.

Spinning and drawing

both result in the production of seamless

parts. Depending on quantities, either process is

cost effective.

One similarity that deep drawing shares

with spinning metal is the ability to manufacture circular

cases. Additionally, deep drawing enables the production of

parts such as rectangles, squares, and cylinders.

And

like metal spinning, deep drawing produces parts from blanks.

Utilizing single piece blanks, common in the deep drawn

process, enables the drawing process to create parts with

deeper shapes.

Typically, the deep drawing press pushes

material from a reel, or single blanks, through multiple

positions. At each position the shape is changed by pressing

or "drawing" the material further down into a progressively

changing set of geometric dies until the final shape is

acquired.

Whether the process requires a single draw

operation, or multiple drawn operations to create the desired

resulting form, largely depends on the metal being used and

the requirements of the finished product.

The part

configuration is limited by the required force to produce the

shape, which is dependant on the size of the drawing press,

the material's malleable characteristics and it��s ability to

be drawn.

In another similar process, single blanks are

held in place and pressed into the cavity of the custom shaped

die to produce the item.

Deep drawing is different from

stamping. Stamping often requires that the

material used be transported along on a strip called a

carrier, through completion until the last operation is

performed on the piece. It does not leave the machine until

the process is complete. Deep drawing utilizes single piece

blanks to permit deeper drawn shape parts. Deep drawing does

utilize strip feed material when draw depths are limited to

the part diameter. The blank is simultaneously cut from the

strip while the draw plug forms the part profile.

There

are many metals suitable for deep drawing including

stainless steel, aluminum,

brass, copper and

cold rolled steel. The only real requirement

is that the metals must be malleable, allowing the part to be

forced into a shape without suffering from excessive stress

damage; resulting in cracks during the deep drawn

process.

Products & Services

Our deep drawn enclosure department specializes in fabricated / prototype cans, deep drawn cans and covers made from various metals and alloys (Ferrous and Non-Ferrous). In addition to drawing your cans, we can hot tin dip (RoHS Compliant) and hot solder dip (60/40 Sn/Pb) your cases and covers.

Capabilities include:- quality high and low volume stampings (miniature to medium part size)

- temporary and permanent tooling

- precision forming

- draw

- deep draw

- progressive, compound, and transfer dies

- plating

- laser marking

- insulation feet installation

- studs

- threaded inserts and pem nuts

- soldering

- terminal populating

- hole piercing

- glass feed through terminals

Deep drawn cans are an attractive alternative for prototype development. Once your prototype design is fixed, our tooling experts will design, machine and assemble the tooling for your low or high volume components.

competitive tooling charges

custom modifications to your specifications

low minimums

small and large production runs

low tooling costs on non-standard cans

| Custom Deep Drawn Products | Deep Drawn Materials | |

|---|---|---|

|

|